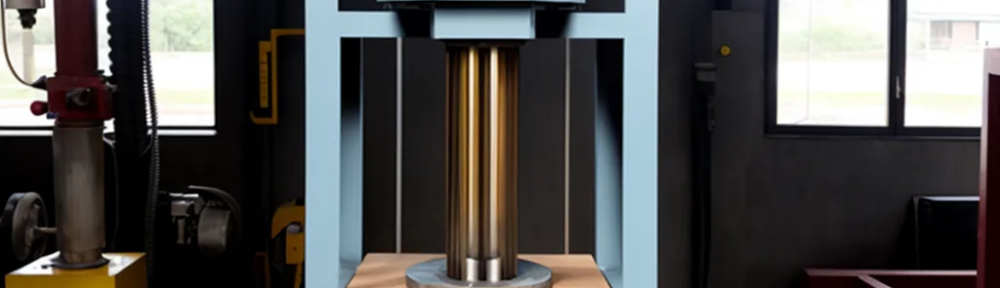

Automated hydraulic press is one of the key tools in manufacturing industries such as automotive, aerospace, and many more. These presses are essential in applications such as metal forming, deep drawing, molding, punching, and stamping. The distinguishing factor between a good and a perfect automated hydraulic press comes down to certain key features. In this article, we’ll delve into 5 things that make for a perfect automated hydraulic press.

High Automation Level:

The level of automation is the first factor that sets apart an exceptional hydraulic press. A perfect automated hydraulic press should have an integrated computerized system that can execute tasks without or with minimal human intervention. This not only speeds up the production process but also minimizes the risk of human errors. Moreover, it should have features such as automatic die changes, touch screen interface, and remote diagnostics for real-time error detection and correction.

Energy Efficiency:

In an era where sustainability and energy efficiency are paramount, a perfect automated hydraulic press should exhibit high energy efficiency. This can be achieved by incorporating energy-saving technologies such as servo motors or variable speed pumps. Moreover, energy recovery systems can convert the kinetic energy produced during the press’s operation back into usable electricity, further enhancing its energy efficiency.

Robustness and Durability:

An excellent automated hydraulic press should be able to withstand long working hours and harsh conditions while maintaining a high level of performance. This means the use of high-quality, durable materials in its construction and the integration of a robust cooling system to prevent overheating during continuous operation. Furthermore, it should have a sturdy frame to reduce vibrations and ensure stable operations.

High Precision and Accuracy:

High precision and accuracy are critical for maintaining the quality of the finished product. The perfect automated hydraulic press should incorporate advanced feedback systems that can accurately monitor and control factors like pressure, speed, and position. These systems, combined with high-quality hydraulic components, can ensure that every operation is executed with the highest precision and consistency.

Safety Features:

Despite high automation levels, human interaction with the hydraulic press can’t be completely ruled out. Safety features include pressure relief valves, safety guards to protect operators from flying debris, Emergency stop buttons that automatically halt operations.

Read more here about some of the most advanced automated hydraulic press machines.